| Availability: | |

|---|---|

| Quantity: | |

Heat Exchanger Tube

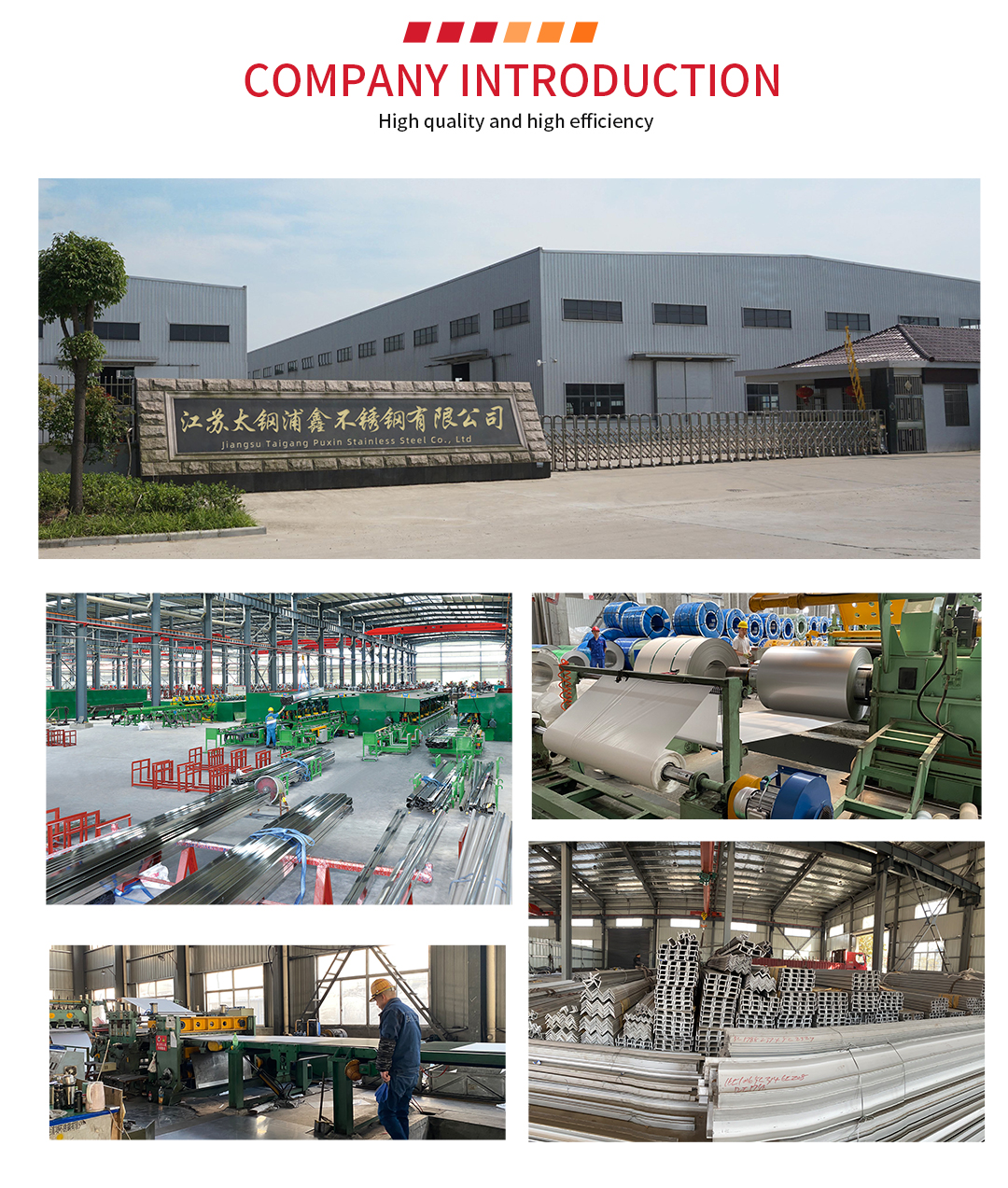

Taigang Puxin

Taigang Puxin's heat exchanger tube program includes imperial and metric sizes, from outside diameter 12 mm up to 40 mm (0.472 to 1.575 in.). Special sizes can be made to order. Taigang Puxin heat exchanger tube are supplied in straight lengths up to 30 meters, or as U-bent tubes.

Lower life-cycle cost with duplex stainless steels

Our portfolio of duplex stainless steels is the widest on the market. Duplex stainless steel heat exchanger tubes perform exceptionally well in a variety of environments and media common in process industries, resulting in lower life-cycle costs.

| Heat exchanger tube materials | |||||

| The tables show our standard materials for heat exchanger tube. Other grades can be offered on request. | |||||

| Duplex stainless steels | |||||

| Grade | UNS | ASTM | EN no. | W.-nr | AFNOR |

| 3RE60 | S31500 | - | 1.4424 | 1.4417 | Z2CND18-05-03 |

| SAF 2205™ | S31803/S32205 | - | 1.4462 | - | Z2CND22-05-03 |

| SAF 2304® | S32304 | - | 1.4362 | 1.4362 | Z2NC23-04AZ |

| SAF 2707 HD™ | S32707 | - | - | - | - |

| SAF 2507® | S32750 | - | 1.441 | - | - |

| High-alloy austenitic stainless steels and nickel alloys | |||||

| Grade | UNS | ASTM | EN steel no. | W.-nr | AFNOR |

| 70 | N06600 | Alloy 600 | - | 2.4816 | - |

| 69 | N06690 | Alloy 690 | 2.4642*** | 2.4642 | NC30FE(RCCM) |

| 60 | N06625 | Alloy 625 | - | - | - |

| 41 | N08825 | Alloy 825 | - | 2.4858 | - |

| 30 | N08800 | - | 1.4558 | 1.4558 | - |

| 28 | N08028 | - | 1.4563 | 1.4563 | - |

| 2RK65™ | N08904 | - | 1.4539 | 1.4539 | Z1NCDU25-20-4 |

| 254 SMO* | S31254 | - | 1.4547 | (1.4529)** | - |

| * 254 SMO is a trademark of Outokumpu OY. | |||||

| ** In brackets, nearest equivalent steel grade | |||||

| *** Not applicable for tube and pipe. Only for information. | |||||

| Austenitic stainless steels | |||||

| Grade | UNS | ASTM | EN steel no. | W.-nr | AFNOR |

| 3R12 | S30403/S30400 | 304L/304 | 1.4306/1.4301 | 1.4306/1.4301 | Z2CN18-10 |

| 3R60™ | S31603/S31600 | 316L/316 | 1.4435/1.4436 | 1.4435/1.4436 | Z2CND17-13 |

| 5R75 | S31635 | 316Ti | 1.4571 | 1.4571 | (Z6CNDT17-12)** |

| 6R35 | S32100/S32109 | 321/321H | 1.4541/1.4940 | 1.4541/1.4878 | (Z6CNT18-10)** |

| Titanium and Zirconium | |||||

| Type of material | Grade(s) | ||||

| Titanium | Pure titanium and titanium grades: | ||||

| 1, 2, 3, 4, 7, 9, 11, 12, 16, 17, 26 and 28 | |||||

| Zirconium | Zirconium 702 (ZR-702) | ||||

| Product standards | |||||

| American standards | European standards | ||||

| Grade | ASTM | ASME | EN | VD TÜV | |

| Duplex | |||||

| SAF 2707 HD™ | A-789 | SA-789 | - | - | |

| SAF 2507® | A-789 | SA-789 | 10216-5 | VD TÜV Blatt 508 | |

| SAF 2205™ | A-789 | SA-789 | 10216-5 | VD TÜV Blatt 418 | |

| SAF 2304® | A-789 | SA-789 | 10216-5 | - | |

| 3RE60 | A-789 | SA-789 | - | - | |

| Ni-Alloy | |||||

| 70 | B-163 B-167 | SB-163 SB-167 | - | VD TÜV Blatt 305 | |

| 69 | B-163 B-167 | SB-163 SB-167 | - | - | |

| 41 | B-163 B-423 | SB-163 SB-423 | - | - | |

| 30 | B-163 B-407 | SB-163 SB-407 | 10216-5 | - | |

| 28 | B-668 | SB-668 | 10216-5 | VD TÜV Blatt 483 | |

| 2RK65™ | A-269 | SB-677 | 10216-5 | VD TÜV Blatt 421 | |

| 254 SMO* | A-213 A-269 | SA-213 SA-269 | 10216-5 | - | |

| Austenitic | |||||

| 5R75 | A-213 | SA-213 | 10216-5 | - | |

| 3R60 | A-213 A-269 | SA-213 | 10216-5 | - | |

| 3R65 | A-213 A-269 | SA-213 | 10216-5 | - | |

| 6R35 | A-213 A-269 | SA-213 | 10216-5 | - | |

| 3R12 | A-213 A-269 | SA-213 | 10216-5 | - | |

U-bent heat exchanger tubes

Taigang Puxin stainless heat exchanger tubes can also be delivered as U-bent tubes*, manufactured according to the common heat exchanger standards. We can use DIN 28179, TEMA RCB 2.31 or various customer specifications. Copies of all specifications are available on request.

Technical parameters

-OD 12.7- 38 mm

-Bending radii from 1.5 x OD up to 1,250 mm. Minimum bending radii for OD over 28 mm after agreement.

-Leg length min. 1,000 mm.

-Leg length max. 12,000 mm.

-Heat treatment for radii up to 1,000 mm.

Heat treatment

If specified, we are equipped to carry out heat treatment of bends plus minimum 150 mm of leg.

-Furnace is computer controlled and all data is recorded.

-We use an Argon protective atmosphere inside the tubes.

-We can supply all types of annealing; solution annealing, stress relieving and stabilization.

Measuring, cutting, deburring and cleaning

-U-bends are measured exactly in accordance with relevant standards.

-All tubes are cut to the specified leg lengths, ends are deburred and the tubes are internally cleaned with air.

-Before packing, both ends of U-bends are capped with plastic caps.

Packing

-In strong, open or closed wooden boxes, depending on destination - max 8,000 kg.

-Ends of tubes protected by plastic caps.

-Vertical separators for each radius.

-Chloride free plastic separators between each row, every 2 meters.

-Each bundle is covered with plastic.

-Customers can provide a packing drawing or we can prepare a packing plan.

-Packing lists, covered with plastic, are placed on each wooden box for easy identification of order details, including exact list of radii and lengths inside.

* Valid for wall thickness less than or equal to 4 mm/0.157 in.

Our heat exhanger tubes are typically used in:

Chemical processing

Condensers

Flue gas cleaning

Evaporators

Feedwater heaters

Gas processing

Hydrometallurgy

Oil refining, petrochemical and gas processing

Phosphoric acid production

Petrochemical processing

Salt evaporation

Seawater-cooled heat exchangers

Urea production

Taigang Puxin's heat exchanger tube program includes imperial and metric sizes, from outside diameter 12 mm up to 40 mm (0.472 to 1.575 in.). Special sizes can be made to order. Taigang Puxin heat exchanger tube are supplied in straight lengths up to 30 meters, or as U-bent tubes.

Lower life-cycle cost with duplex stainless steels

Our portfolio of duplex stainless steels is the widest on the market. Duplex stainless steel heat exchanger tubes perform exceptionally well in a variety of environments and media common in process industries, resulting in lower life-cycle costs.

| Heat exchanger tube materials | |||||

| The tables show our standard materials for heat exchanger tube. Other grades can be offered on request. | |||||

| Duplex stainless steels | |||||

| Grade | UNS | ASTM | EN no. | W.-nr | AFNOR |

| 3RE60 | S31500 | - | 1.4424 | 1.4417 | Z2CND18-05-03 |

| SAF 2205™ | S31803/S32205 | - | 1.4462 | - | Z2CND22-05-03 |

| SAF 2304® | S32304 | - | 1.4362 | 1.4362 | Z2NC23-04AZ |

| SAF 2707 HD™ | S32707 | - | - | - | - |

| SAF 2507® | S32750 | - | 1.441 | - | - |

| High-alloy austenitic stainless steels and nickel alloys | |||||

| Grade | UNS | ASTM | EN steel no. | W.-nr | AFNOR |

| 70 | N06600 | Alloy 600 | - | 2.4816 | - |

| 69 | N06690 | Alloy 690 | 2.4642*** | 2.4642 | NC30FE(RCCM) |

| 60 | N06625 | Alloy 625 | - | - | - |

| 41 | N08825 | Alloy 825 | - | 2.4858 | - |

| 30 | N08800 | - | 1.4558 | 1.4558 | - |

| 28 | N08028 | - | 1.4563 | 1.4563 | - |

| 2RK65™ | N08904 | - | 1.4539 | 1.4539 | Z1NCDU25-20-4 |

| 254 SMO* | S31254 | - | 1.4547 | (1.4529)** | - |

| * 254 SMO is a trademark of Outokumpu OY. | |||||

| ** In brackets, nearest equivalent steel grade | |||||

| *** Not applicable for tube and pipe. Only for information. | |||||

| Austenitic stainless steels | |||||

| Grade | UNS | ASTM | EN steel no. | W.-nr | AFNOR |

| 3R12 | S30403/S30400 | 304L/304 | 1.4306/1.4301 | 1.4306/1.4301 | Z2CN18-10 |

| 3R60™ | S31603/S31600 | 316L/316 | 1.4435/1.4436 | 1.4435/1.4436 | Z2CND17-13 |

| 5R75 | S31635 | 316Ti | 1.4571 | 1.4571 | (Z6CNDT17-12)** |

| 6R35 | S32100/S32109 | 321/321H | 1.4541/1.4940 | 1.4541/1.4878 | (Z6CNT18-10)** |

| Titanium and Zirconium | |||||

| Type of material | Grade(s) | ||||

| Titanium | Pure titanium and titanium grades: | ||||

| 1, 2, 3, 4, 7, 9, 11, 12, 16, 17, 26 and 28 | |||||

| Zirconium | Zirconium 702 (ZR-702) | ||||

| Product standards | |||||

| American standards | European standards | ||||

| Grade | ASTM | ASME | EN | VD TÜV | |

| Duplex | |||||

| SAF 2707 HD™ | A-789 | SA-789 | - | - | |

| SAF 2507® | A-789 | SA-789 | 10216-5 | VD TÜV Blatt 508 | |

| SAF 2205™ | A-789 | SA-789 | 10216-5 | VD TÜV Blatt 418 | |

| SAF 2304® | A-789 | SA-789 | 10216-5 | - | |

| 3RE60 | A-789 | SA-789 | - | - | |

| Ni-Alloy | |||||

| 70 | B-163 B-167 | SB-163 SB-167 | - | VD TÜV Blatt 305 | |

| 69 | B-163 B-167 | SB-163 SB-167 | - | - | |

| 41 | B-163 B-423 | SB-163 SB-423 | - | - | |

| 30 | B-163 B-407 | SB-163 SB-407 | 10216-5 | - | |

| 28 | B-668 | SB-668 | 10216-5 | VD TÜV Blatt 483 | |

| 2RK65™ | A-269 | SB-677 | 10216-5 | VD TÜV Blatt 421 | |

| 254 SMO* | A-213 A-269 | SA-213 SA-269 | 10216-5 | - | |

| Austenitic | |||||

| 5R75 | A-213 | SA-213 | 10216-5 | - | |

| 3R60 | A-213 A-269 | SA-213 | 10216-5 | - | |

| 3R65 | A-213 A-269 | SA-213 | 10216-5 | - | |

| 6R35 | A-213 A-269 | SA-213 | 10216-5 | - | |

| 3R12 | A-213 A-269 | SA-213 | 10216-5 | - | |

U-bent heat exchanger tubes

Taigang Puxin stainless heat exchanger tubes can also be delivered as U-bent tubes*, manufactured according to the common heat exchanger standards. We can use DIN 28179, TEMA RCB 2.31 or various customer specifications. Copies of all specifications are available on request.

Technical parameters

-OD 12.7- 38 mm

-Bending radii from 1.5 x OD up to 1,250 mm. Minimum bending radii for OD over 28 mm after agreement.

-Leg length min. 1,000 mm.

-Leg length max. 12,000 mm.

-Heat treatment for radii up to 1,000 mm.

Heat treatment

If specified, we are equipped to carry out heat treatment of bends plus minimum 150 mm of leg.

-Furnace is computer controlled and all data is recorded.

-We use an Argon protective atmosphere inside the tubes.

-We can supply all types of annealing; solution annealing, stress relieving and stabilization.

Measuring, cutting, deburring and cleaning

-U-bends are measured exactly in accordance with relevant standards.

-All tubes are cut to the specified leg lengths, ends are deburred and the tubes are internally cleaned with air.

-Before packing, both ends of U-bends are capped with plastic caps.

Packing

-In strong, open or closed wooden boxes, depending on destination - max 8,000 kg.

-Ends of tubes protected by plastic caps.

-Vertical separators for each radius.

-Chloride free plastic separators between each row, every 2 meters.

-Each bundle is covered with plastic.

-Customers can provide a packing drawing or we can prepare a packing plan.

-Packing lists, covered with plastic, are placed on each wooden box for easy identification of order details, including exact list of radii and lengths inside.

* Valid for wall thickness less than or equal to 4 mm/0.157 in.

Our heat exhanger tubes are typically used in:

Chemical processing

Condensers

Flue gas cleaning

Evaporators

Feedwater heaters

Gas processing

Hydrometallurgy

Oil refining, petrochemical and gas processing

Phosphoric acid production

Petrochemical processing

Salt evaporation

Seawater-cooled heat exchangers

Urea production