| Availability: | |

|---|---|

| Quantity: | |

Steel Sheet Pile

Sheet piles are sections of sheet materials with interlocking edges that are driven into the ground to provide earth retention and excavation support. Sheet piles are most commonly made of steel.

Sheet piles are commonly used for retaining walls, land reclamation, underground structures such as car parks and basements, in marine locations for riverbank protection, seawalls, cofferdams, and so on. Permanent steel sheet piles are designed to provide a long service life. Vibratory hammers are typically used to install sheet piles. If soils are too hard or dense, an impact hammer can be used to complete the installation. For the development of sheet piles, there are two main techniques: hot-rolled and cold-formed. At high temperatures, hot rolled piles are produced and the interlocks appear to be stronger and more resilient.

TGPX has gained a reputation as one of the leading steel suppliers and manufacturers. We have the experience and resources to handle, store, and ship high-quality steel products to clients both domestically and internationally. We can serve your immediate needs from over 50,000 tons of steel we carry in stock.

Our experienced sales consultants can also work with you to meet any special requirements — Quote Online

Sections

Steel sheet piling is manufactured in three basic configurations: “Z”, “U” and “straight” (flat). Historically, such shapes have been hot-rolled products produced at structural mills. Like other shapes such as beams or channels, the steel is heated in a furnace and then passes through a series of rolls to form the final shape and the interlock, which allows the sheet piles to be threaded together. Some use a cold-forming process in which steel coil is rolled at room temperature into the final sheet pile shape. Cold formed sheet piles have hook and grip interlocks.

Z-Sections

The essential characteristics of Z-sections include the continuous form of the web and the location of the interlock symmetrically on each side of the neutral axis.

Both aspects create a positive influence on the section modulus. The AZ® series, a section with extraordinary characteristics and the proven qualities of the Larssen interlock, has the following advantages:

– extremely competitive section-modulus-to-mass ratio;

– increased inertia for reduced deflection;

– large width, resulting in competitive installation performance;

– good corrosion resistance, the steel being thickest at the critical corrosion points.

U-Sections

The advantages of U-sections include:

– a wide range of sections forming several series with various geometrical characteristics, allowing a technically and economically optimal choice for each specific project;

– the combination of great profile depth with large flange thickness giving excellent mechanical properties;

– the symmetrical form of the single element has made these sheet piles particularly convenient for re-use;

– the possibility of assembling and crimping the piles into pairs at the mill improves installation quality and performance;

– easy fixing of tie-rods and swivelling attachments, even under water;

– great corrosion resistance, with the steel section being thickest at the critical corrosion points.

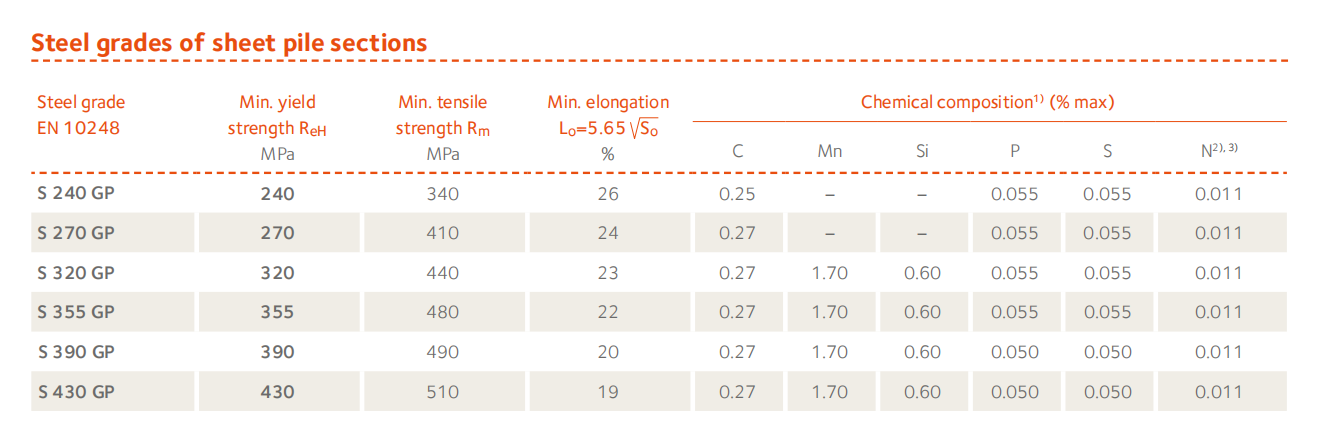

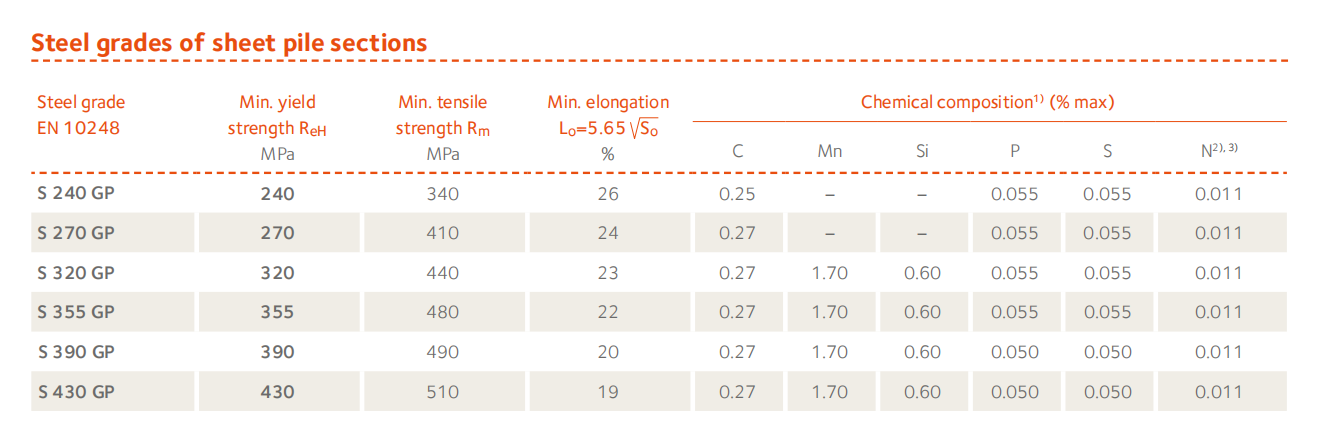

Steel Grades Of Sheet Pile Sections

Hot Rolled Sheet Piles

Hot Rolled Sheet Piles are formed by profiling the steel with high temperatures as the rolling process occurs. Typically, hot rolled sheet piles are produced to BS EN 10248 Part 1 & 2. Greater thicknesses are achievable than cold rolled sheet piles. The interlocking clutch tends to be tighter as well.

Cold Formed & Cold Rolled Sheet Piles

Cold Rolling and Forming processes are when the steel sheet pile is profiled at room temperature. The profile thickness is constant along the width of the profile. Typically, cold rolled/formed sheet piles are produced to BS EN 10249 Part 1 & 2. Cold Rolling occurs in a continuous section from hot rolled coil whereas Cold Forming occurs is discrete lengths either from decoiled hot rolled coil or plate. A wide range of widths and depths are achievable.

Production Process

Applications

Steel sheet piles are used worldwide for the construction of quays walls and breakwaters in harbours, locks, and for bank reinforcement on rivers and canals. Other applications are temporary cofferdams in land and in water, permanent bridge abutments, retaining walls for underpasses or underground car parks, impervious containment walls, etc.

Please reach out to our experienced sales manager with your requirements & we will be able to advise on stock availability and lead times.

Sheet piles are sections of sheet materials with interlocking edges that are driven into the ground to provide earth retention and excavation support. Sheet piles are most commonly made of steel.

Sheet piles are commonly used for retaining walls, land reclamation, underground structures such as car parks and basements, in marine locations for riverbank protection, seawalls, cofferdams, and so on. Permanent steel sheet piles are designed to provide a long service life. Vibratory hammers are typically used to install sheet piles. If soils are too hard or dense, an impact hammer can be used to complete the installation. For the development of sheet piles, there are two main techniques: hot-rolled and cold-formed. At high temperatures, hot rolled piles are produced and the interlocks appear to be stronger and more resilient.

TGPX has gained a reputation as one of the leading steel suppliers and manufacturers. We have the experience and resources to handle, store, and ship high-quality steel products to clients both domestically and internationally. We can serve your immediate needs from over 50,000 tons of steel we carry in stock.

Our experienced sales consultants can also work with you to meet any special requirements — Quote Online

Sections

Steel sheet piling is manufactured in three basic configurations: “Z”, “U” and “straight” (flat). Historically, such shapes have been hot-rolled products produced at structural mills. Like other shapes such as beams or channels, the steel is heated in a furnace and then passes through a series of rolls to form the final shape and the interlock, which allows the sheet piles to be threaded together. Some use a cold-forming process in which steel coil is rolled at room temperature into the final sheet pile shape. Cold formed sheet piles have hook and grip interlocks.

Z-Sections

The essential characteristics of Z-sections include the continuous form of the web and the location of the interlock symmetrically on each side of the neutral axis.

Both aspects create a positive influence on the section modulus. The AZ® series, a section with extraordinary characteristics and the proven qualities of the Larssen interlock, has the following advantages:

– extremely competitive section-modulus-to-mass ratio;

– increased inertia for reduced deflection;

– large width, resulting in competitive installation performance;

– good corrosion resistance, the steel being thickest at the critical corrosion points.

U-Sections

The advantages of U-sections include:

– a wide range of sections forming several series with various geometrical characteristics, allowing a technically and economically optimal choice for each specific project;

– the combination of great profile depth with large flange thickness giving excellent mechanical properties;

– the symmetrical form of the single element has made these sheet piles particularly convenient for re-use;

– the possibility of assembling and crimping the piles into pairs at the mill improves installation quality and performance;

– easy fixing of tie-rods and swivelling attachments, even under water;

– great corrosion resistance, with the steel section being thickest at the critical corrosion points.

Steel Grades Of Sheet Pile Sections

Hot Rolled Sheet Piles

Hot Rolled Sheet Piles are formed by profiling the steel with high temperatures as the rolling process occurs. Typically, hot rolled sheet piles are produced to BS EN 10248 Part 1 & 2. Greater thicknesses are achievable than cold rolled sheet piles. The interlocking clutch tends to be tighter as well.

Cold Formed & Cold Rolled Sheet Piles

Cold Rolling and Forming processes are when the steel sheet pile is profiled at room temperature. The profile thickness is constant along the width of the profile. Typically, cold rolled/formed sheet piles are produced to BS EN 10249 Part 1 & 2. Cold Rolling occurs in a continuous section from hot rolled coil whereas Cold Forming occurs is discrete lengths either from decoiled hot rolled coil or plate. A wide range of widths and depths are achievable.

Production Process

Applications

Steel sheet piles are used worldwide for the construction of quays walls and breakwaters in harbours, locks, and for bank reinforcement on rivers and canals. Other applications are temporary cofferdams in land and in water, permanent bridge abutments, retaining walls for underpasses or underground car parks, impervious containment walls, etc.

Please reach out to our experienced sales manager with your requirements & we will be able to advise on stock availability and lead times.